5 Essential Elements For forklift lights safety

5 Essential Elements For forklift lights safety

Blog Article

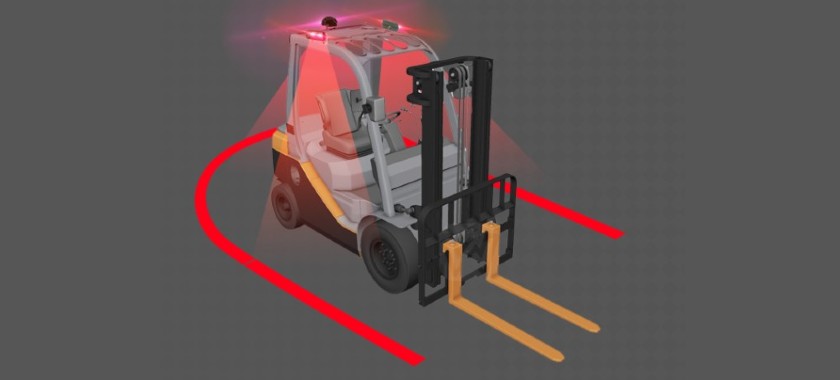

The lights protect against rear-stop collision and foot injuries by building a visible boundary throughout the forklift. The sturdy style and design of these safety lights might also stand up to vibrations and shocks as forklifts are devoid of any conventional suspension set up.

How do mishaps come about all over forklifts? With all the sounds they develop, shouldn’t personnel and pedestrians have the capacity to stay away from them?

When hundreds on the forklift are uneven or unbalanced, they might speedily change and tumble for the duration of motion, amounting to accidents or fatalities. Excessive speed although carrying a load might cause the load to idea around and drop.

When personnel are alerted by the intense light moving over the ground, they know a vehicle is on how. Considering the fact that the light moves only if the motor vehicle does, pedestrians can realize once the motor vehicle is stationary or over the move.

It's a precise marker with two zones, Warning and Danger, that are indicated by a LED light and audible sounder for the pedestrian and equipment driver simultaneously.

36% of serious forklift relevant injuries entail anyone in addition to the driver. Which is in which the auto technique warning mild allows stop unsafe collisions.

In facilities housing equally sorts of equipment, overhead crane lights Engage in a significant job in ensuring security. These lights aid forklift operators as well as other employees in correctly analyzing the posture of the overhead crane's load, contributing towards the safety and avoidance of prospective hazards.

To prevent these kinds of incidents from going on, make certain that masses are well centered about the forks and stay clear of excessive speed when transporting a pallet forklift lights safety by using a major load.

Do you need any of these forklift lights? The short answer is: it relies upon. The optional lights you place with your forklifts will rely on your specific operation.

You might also be encouraged to mount red zone mild, commonly used to mark out a pink zone alongside the forklift. This mild will be to demarcate a secure distance for forklift lights safety everyone Doing work while in the warehouse or workshop.

Visual inspection: Operators must inspect the forklift for forklift lights safety almost any obvious indications of injury, for instance leaks or worn-out tires.

It’s crucial that you Notice that strobe lights, forklift lights safety blue spotlights, and crimson side pedestrian lights might not be the only option for a few programs. In reality, there are several circumstances exactly where the use forklift lights safety of these optional lights can in fact minimize safety.

Employing these hand signals can improve transparency while in the place of work via using these hand signals. Doing this assists in ensuring far better conversation and understanding among operators and pedestrians.

When driving a forklift in reverse, it may be demanding to discover what is behind you. Blue safety lights will warn pedestrians or other operators when you might have a confined rear perspective.